What a year: what stress, what challenge, what change; what resilience, what teamwork, what an effort.

And what learnings! As we come to the end of this year of all years, a year in which we have all been put to the test like never before, we have paused for thought to examine what we have learned through it all:

NZ Inc. is in a way better position than many thought earlier this year

The blizzard of stories in March and April of lockdowns, headwinds, unemployment, casualties and economic retrenchment – and even another great Depression – did not make for pretty reading. It is to the Government’s credit therefore that the economy has in many sectors been insulated by measures it put in place. Although the hospitality, retail, tourism and travel sectors have been hit hard, today’s headline unemployment number of 5.3% is nowhere near the prediction of 10% we saw in May.

Available GDP information shows that the much-desired V-shaped recovery has taken place so far, and is likely to be followed by a slow rise up into 2022, when it is predicted to accelerate again. Lockdowns have been far less costly than feared – for many – and relatively strong positivity in the workforce about job security is driving investment confidence.

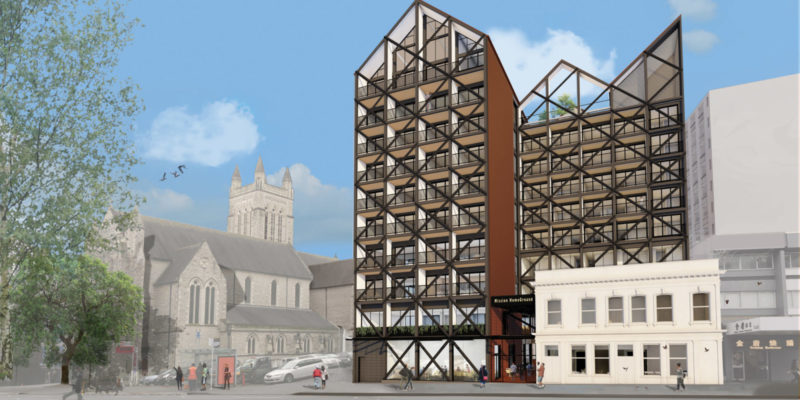

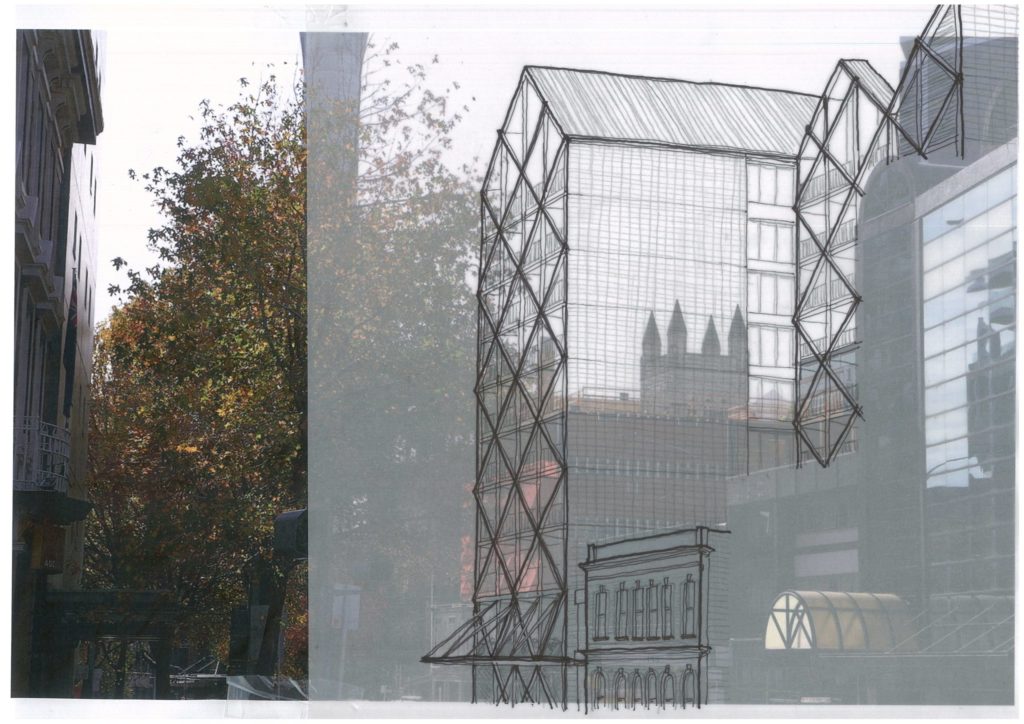

We do have a deep-rooted structural issue with housing supply, and commercial and retail property are constrained. Consents are rising for dwellings, although their slow approval pace is still hurting growth, and development sections are being snapped up. Heightened demand in the industrial sector is also driving land prices up as retailers race to meet online shopping demands.

Low interest rates are fantastic for the economy and confidence, but take care

With the $10 billion we usually spend nationally on overseas travel filtering around the Kiwi economy right now, many Kiwis are proving to be quite resilient. And, with interest rates so low, people are using their banks’ money to drive yield from assets. Continuing liquidity in the market is driven partly by quantitative easing, and the Government is evidently keen to keep pumping it in, so there is plenty of money to be lent. The banks are flush with cash, if you can put the business case together to access it.

In this environment, due diligence has to be key: do development projects stack up, and what does the margin look like? In a fast-moving world, it can be tempting to rush projects. We caution that project design must be where it needs to be, and we would advise against rushing pricing. The little you save in interest rates at the moment you’ll burn through in poor planning costs downstream.

Beware the ripple effect

Although the construction sector hasn’t gone through a tourism-style extended halt, busy (when permitted) consistently this year, it’s worth saying that the larger size projects we’re busy on now are ones we have been working on for a year or two. It’s only when the pre-existing projects finish that we will see if and how new projects are going to come through. The rubber won’t hit the road on this for quite a while. When Commercial Bay, NZICC, The Pacifica and other big developments are completely finished, what will the picture look like?

There have been many projects coming on stream in this last quarter however there will be large gaps to fill the void for the developments noted above.

What’s stimulus comes next?

Another big question is how the Government can/will keep the economy going with the debt they are carrying. They won’t be able to spend for ever – so how do they stimulate things? Investors are still pretty hungry for yield, and are driven to property assets based on historically low interest rates. FOMO is a factor at present, without doubt. However, at some point the momentum may slow down in the event of aggressive Government policy in areas such as LVRs and possible debt to income ratios being introduced.

Expect a flight to commercial property

If a longer-term recovery is on the cards, we can expect to see continued house price inflation for a while yet. However, we anticipate a flight to commercial property as people miss out on the dwindling number of residential sections and investment opportunities, so they are already turning to purchasing old commercial buildings with opportunity to add value and obtain a reasonable yield. In our world, this means that feasibilities will be tested strongly. The question will be this: with land prices so high, will developments stack up?

Be responsive

The way in which our team responded to such a disruptive year has been a real highlight for us. It was almost seamless, despite being given 24 hours’ notice to vacate our offices in March. The second time was almost natural… The way everyone adapted and got on with what was happening meant we didn’t really skip a beat. With everyone working remotely, checking in on each other, pulled us all in closer together.

Three-legged stools work well

Our biggest learning, and new company mantra as we move into 2021, is to be a three-legged stool. This means we need to :

1. Be efficient

In 2019 our team worked a total of 22,000 man hours. In 2020 this jumped to 30,000, and we’re doing more work in more areas than ever before. So, while we’re working on our core client base and have a steady influx of new enquiries coming through, it is a tight and competitive place out there in the market. Keeping our product at a high quality as we work at speed is a key focus for us. We had thought so much about flexibility, and then it got forced on us. So one message is: Just do it. 2020 gave us the platform to introduce real flexibility and digital efficiency, and we continue to develop our BIM strategy and diversify our portfolio of skills and successes.

2. Be prepared

To be fast on our feet, nimble and quick to react, we needed to be ready. This means having the tools, resources and people in place and prepared to act when needed. In 2019, public sector, residential and retail sectors dominated our work. In 2020, although subdivisions slid down our scale, industrial and residential projects moved up into greater prominence. It also means we need to think further ahead. 2020 has been good for this: when we started the business, we didn’t really know what was coming beyond three months, but now because of the situation this year we are thinking so much further ahead.

3. Be connected

Now more than ever we need to keep up communication, making it front and centre: internally and externally. We have seen that the importance of diversity through our portfolio is hugely critical. Although it is the same for any business, when you get a sudden event it drives home how important it is to maintain connections even if you’re not currently working with them.

Diversity is our way forward

Diversity of work, diversity of team. A great thing about White Associates is that our team has become diverse through our natural culture, rather than through a process of positive discrimination. Although this is an area we’re always working on, it is good to realise that our stats show that the diversity of our team is on the rise, women now making up 38%, and eight cultures are represented in our team today. To take this further in 2021, we will be working to find out more about each other’s cultures, and to celebrate them more intentionally, so we can celebrate our individuality.

Thank you all

In a tough year, we have come through it well as a team to deliver services at an exceptional level. It’s been tiring for us all, but extremely rewarding to see such personal and project progress. The thing we value most, time and again, is the magic that happens when project teams come together truly collaboratively to deliver. It has made 2020 special in many ways, and for that we thank you, as well as for the opportunities you give us.

And to keep the conversation going, we’d love to know if these lessons that we have learned are in any way similar to yours!

One last thing: